New ROCLINK 800 forum

A blog isn’t best way for readers to view and ask questions from fellow users. So, if you look to the right you should see a link to a free forum I created. Hopefully, this forum will be a place where users and ask each other for help and make it easier to find solutions.

If anyone has any questions about the blog, or this forum … feel free to ask here in the comments. If you need new categories and/or topics in this forum, please let me know. I’m not an expert on this free forum software, so try to see if you can create them yourself. If you cannot, I will see what I can do for you!

Enjoy!

New Version, 2.30 Released

Just to let everyone know, ROCLINK 800 version 2.30 was released on December 3, 2013. Here is the list of items addressed from v2.20 to 2.30:

Version 2.20 – 2.30 (02-Dec-2013)

- Added support for ROC800L enhancements including transactional history retrieval, generation and extraction of Flow-Cal liquid .cfx files, added support for user weighted averaging technique for meter history points and liquid history wizard option.

- Added support for IEC62591 discrete devices and variables (RL80000003596)

- Added support for new API 21.1 2011 compliant averaging technique in the FB107 product (RL80000003163)

- Added support for AGA3 2012 flow calculation option in the ROC800, ROC800L, and FB107 products.

- Added support of a configurable timeout for import point data on RTU Network installations for ROC800 and FB107 products.

- Restored Modbus configuration after firmware upgrade of ROC800L unit (RL80000003604)

- Resolved issue with daylight savings time parameters not getting set to proper default values when the feature is enabled on a ROC800 unit (RL80000003612)

- Clamped Modbus master poll delay to a minimum of 1 second preventing the possibility of overloading ROC800, ROC800L, and DL8000 units (RL80000003576, RL80000003577, RL80000003578)

Click here to get to the main site, then click on the Technical Support to get the latest version (some hoops to jump through if you don’t have a SupportNet login … just email the support team).

New Version … 1.89

Today, I watched the installer get built. That means, despite having actually compiled and built the 1.89 executable (myself), we’re that much closer to release. Soon, it’ll be available for download from SupportNet. Questions?

Integer math the easy way?

Perhaps this is well-known to many Visual Basic programmers, but today I learned about a quirky way of using the division symbol. Specifically, if you need to perform integer math in a ROCLINK 800 custom user display expression, this might be handy. See below…

Notice how I used the forward slash to perform floating-point division. Next, look how using the back slash changes the result…

If I hadn’t pointed this out, would you have noticed?

The downside I see right away to using this method is during debugging. Your peers might gloss over your cleverness and suspect the bug is elsewhere (or, if you’re like me … the next day I would probably have forgotten). Therefore, I suggest liberal use of code comments.

Howto: Sampler/Odorizer

The ROC300-Series and FloBoss 407 do not include the built-in feature of a sampler/odorizer in firmware. However, we can accomplish the same thing using an FST (Function Sequence Table)!

For our example, we are going to turn on (pulse for one second) a discrete output for every 1,000 units of gas the flow computer measures.

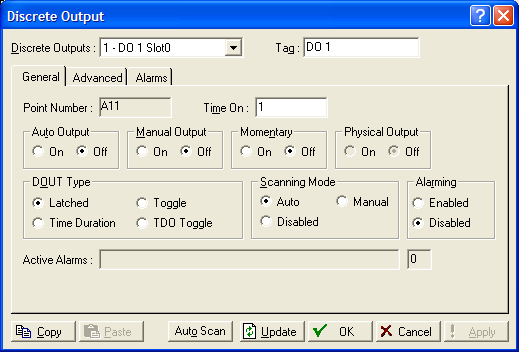

To start, we need to configure our discrete output (Configure > I/O > DO Points) for Latched type … similar to:

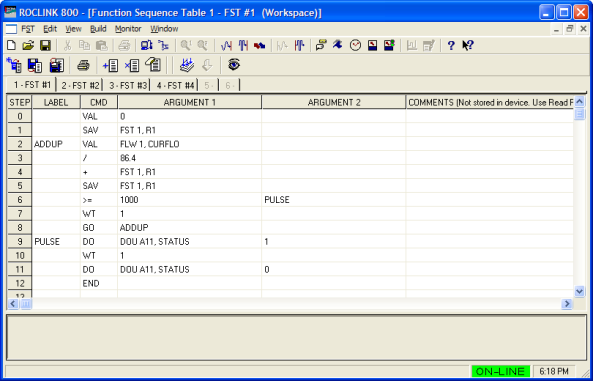

Next, open the FST Editor (Utilities > FST Editor).

Compose your FST similar to:

- Step 0: Clear the Results Register by making it 0.

- Step 1: Clear FST #1, Register #1

- Step 2: Get the value of the instantaneous flow rate parameter from the desired meter run. This number is automatically saved in the Results Register.

- Step 3: Divide it by 86.4 (the number of seconds in one day, divided by 1000 … 86.4 = 86,400 / 1000).

- Step 4: Add this number to the number stored in Register #1. This is where the FST gradually sums the flow volume until we reach our desired value of “1000” units.

- Step 5: The gradual summation is currently stored in the Results Register (RR), but we need to store it in a more-permanent location … so, we’re going to continually overwrite Register #1.

- Step 6: If RR is greater than, or equal, to 1000 .. jump to the label defined in ARGUMENT 2, otherwise, continue to the next STEP.

- Step 7: Suspend execution of the FST for one second. We do this to prevent the FST from consuming too many resources from the CPU. If we did not force the FST to suspend, the FST would never allow other tasks to execute … such as historical data accumulation, flow calculations, I/O processing, communications, etc.

- Step 8: Now we jump to ARGUMENT 1’s label.

- Step 9: Change the discrete output’s (DO) Status parameter to 1 (turns it ON).

- Step 10: Suspend FST execution for one second (the amount of time we want to ‘pulse’ our DO).

- Step 11: Change the DO Status parameter back to it’s original value of OFF.

- Step 12: Restart the FST back at STEP 0.

Hopefully, this helps someone get familiar with the various FST commands and how to implement their own sample/odorizer.

DISCLAIMER: This is just an example … in no way should you attempt to use this unless you’ve thoroughly tested the FST’s functionality in your equipment, under your conditions. I assume no responsibility if this doesn’t work as expected.

Welcome to the *unofficial* ROCLINK blog!

If you are an customer of Emerson Process Management’s line of flow computers:

- ROC300-Series

- ROC306

- ROC312

- ROC364

- ROC800-Series

- ROC809

- ROC827 Series 1

- ROC827 Series 2

- FloBoss 100-Series

- FloBoss 103

- FloBoss 104

- FloBoss 107

- FloBoss 407

- FloBoss 500-Series

- FloBoss 503

- FloBoss 504

… undoubtedly you have some form of ROCLINK software installed on your computer. ROCLINK configuration software has a few incarnations…

- DOS ROCLINK

- ROCLINK for Windows

- ROCLINK 800

For the most part, this blog is all about ROCLINK 800. The idea behind this blog is to provide tips & tricks, howtos, and examples so that you explore and learn new things about how to use ROCLINK 800 for maximum value. Hopefully, you’ll learn a few things along the way.

As with any blog, comments are definitely encouraged … so feel free to post your questions and/or thoughts.