Archive

Howto: Sampler/Odorizer

The ROC300-Series and FloBoss 407 do not include the built-in feature of a sampler/odorizer in firmware. However, we can accomplish the same thing using an FST (Function Sequence Table)!

For our example, we are going to turn on (pulse for one second) a discrete output for every 1,000 units of gas the flow computer measures.

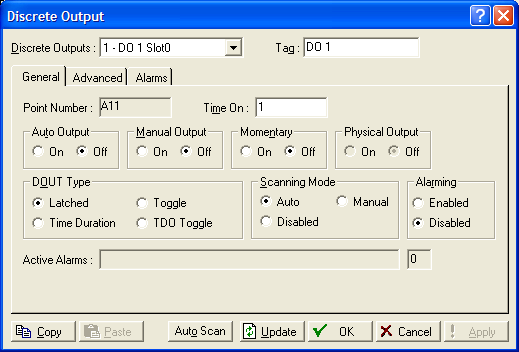

To start, we need to configure our discrete output (Configure > I/O > DO Points) for Latched type … similar to:

Next, open the FST Editor (Utilities > FST Editor).

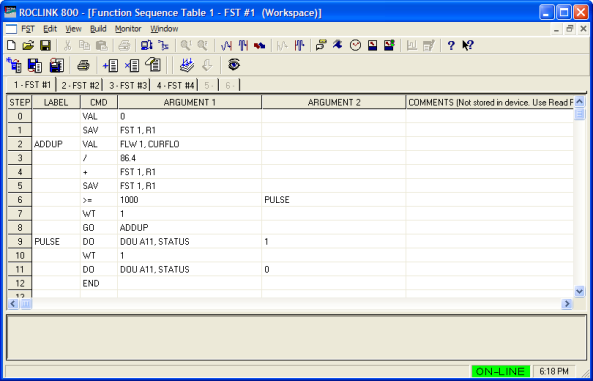

Compose your FST similar to:

- Step 0: Clear the Results Register by making it 0.

- Step 1: Clear FST #1, Register #1

- Step 2: Get the value of the instantaneous flow rate parameter from the desired meter run. This number is automatically saved in the Results Register.

- Step 3: Divide it by 86.4 (the number of seconds in one day, divided by 1000 … 86.4 = 86,400 / 1000).

- Step 4: Add this number to the number stored in Register #1. This is where the FST gradually sums the flow volume until we reach our desired value of “1000” units.

- Step 5: The gradual summation is currently stored in the Results Register (RR), but we need to store it in a more-permanent location … so, we’re going to continually overwrite Register #1.

- Step 6: If RR is greater than, or equal, to 1000 .. jump to the label defined in ARGUMENT 2, otherwise, continue to the next STEP.

- Step 7: Suspend execution of the FST for one second. We do this to prevent the FST from consuming too many resources from the CPU. If we did not force the FST to suspend, the FST would never allow other tasks to execute … such as historical data accumulation, flow calculations, I/O processing, communications, etc.

- Step 8: Now we jump to ARGUMENT 1’s label.

- Step 9: Change the discrete output’s (DO) Status parameter to 1 (turns it ON).

- Step 10: Suspend FST execution for one second (the amount of time we want to ‘pulse’ our DO).

- Step 11: Change the DO Status parameter back to it’s original value of OFF.

- Step 12: Restart the FST back at STEP 0.

Hopefully, this helps someone get familiar with the various FST commands and how to implement their own sample/odorizer.

DISCLAIMER: This is just an example … in no way should you attempt to use this unless you’ve thoroughly tested the FST’s functionality in your equipment, under your conditions. I assume no responsibility if this doesn’t work as expected.